A Lasting Tribute: Inside First-urn's Process of Creating Wooden Pet Urns for Ashes

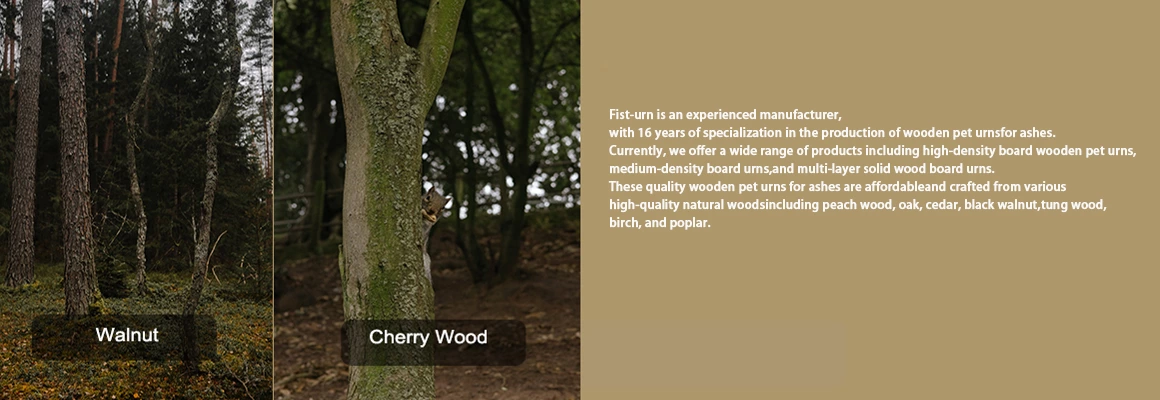

First-urn is an experienced factory with 16 years specializing in wooden urns. At present, we deal with the following categories: high density plywood urns, medium density plywood urns, multi-layered solid wood urns and other pet urns with good quality and good price. Not only that, we also have pet urns made of natural wood processing, such as mahogany, oak, cedar, black walnut, tung, birch, linden and other various high quality raw materials.

Cedar pet urns are particularly popular in the UK. Cedar urns have a unique look with a fresh grain and a staggered pattern on each side. In addition, in the production and processing grinding and polishing links, we are carefully polished each face has a pattern, and even pay great attention to the appearance and tactile feeling, when you get a good cedar wood urn from us, you will feel that it is with fragrance, clear grain, and has a very high degree of ornamental properties. Then the cedar wood urn can be perfectly placed at home as a decorative ornament to comfort our hearts for the loss of our pets and to express our remembrance of our beloved pets.

We are a wooden urn factory, can help you process and design different appearance, process link, we are step by step to control the quality requirement standard. Not only real to the industry standard, but higher than the industry requirements. Because we are from the source to help you control the supply of materials, precision control of cutting density, so that the assembly is more tight, tight. Below, the introduction of our factory has what the main equipment process link, so that you are more familiar with the factory workshop workshop.

Our Wooden Pet Urns for Ashes: A Step-by-Step Process

At First-urn, a leading cremation urns manufacturer, we take pride in our meticulous process of crafting wooden pet urns for ashes. Here’s what goes into the making of each urn:

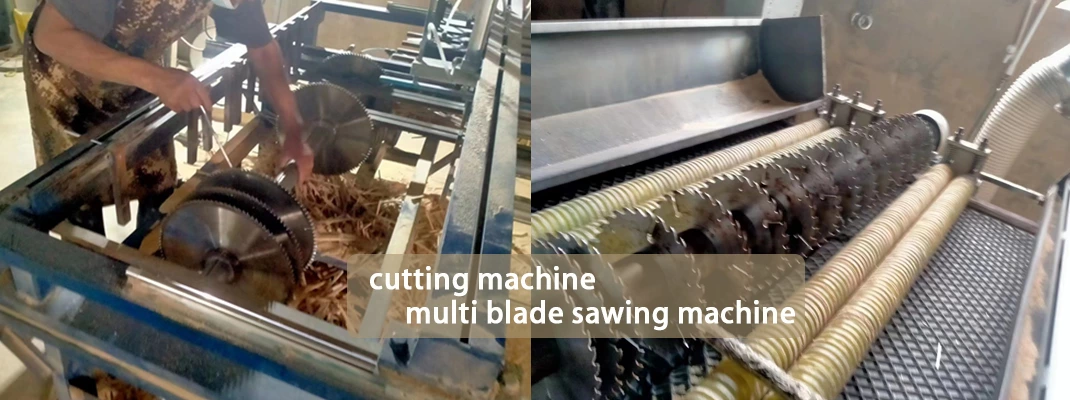

Cutting

In order to produce beautiful wooden urns, it is necessary to determine the design of the urn and check that the wood is dry and free from defects. If the moisture content of the wood is more than 8-12%, it means that this piece of wood contains too much moisture and it is necessary to remove the inferior wood and continue the technical drying of the piece of wood.

If the raw material wood selection is good, then there is a need for further selection of cutting tools, the need to use imported cutting tools to ensure cutting accuracy and quality. At the same time, the cutting parameter settings, including cutting speed, cutting depth, cutting shape and wood species, should be adjusted. Finally, according to the designed drawings, we use the cutting machine with adjusted parameters to process the wood.

We have prepared dry wood, with the choice of imported knives, the type of knife is more based on the type of wood and cutting requirements for selection, in order to avoid poor cutting lead to deformation of wood. When cutting wood, you need to pay attention to the following relevant points of attention:

**Working the wood

*Cut the wood to the required size.

*Sand or plane the surface of the wood to make it smooth and even.

**Cut at a 45 degree angle.

*Cut the wood at a 45 degree angle using special knives to ensure that the 45 degree intersection of the bevelled cuts of each plank can be combined.

*Replace the knives regularly to maintain blade sharpness and cutting accuracy.

Assembling the urn

We have cut the wood into regular planks and then assembled the urn according to the pre-established design drawings, making sure that the joints between the planks are tight and strong. How do you ensure that the different shapes of the planks fit together? By using the Mortise and Tenon method, generally when using oblique Mortise and Tenon joints, different timbers will be combined at a 45 degree oblique angle, resulting in

The result is a unique, solidly constructed urn. In addition to the joining process described above, we also use wood glue or nails to secure the boards to ensure that the wooden urn is structurally sound.

Sanding

Our wooden urns need to be sanded several times during the manufacturing process.

Firstly, after cutting the wood, it needs to be sanded once, this process is mainly to remove the burrs and bumps on the surface of the wood.

And our sanding urn main operation workflow:

Use sandpaper to sand the surface of the urn to remove small burrs on the surface of the wood.

Use polishing machine to polish the surface of the urn to make the surface of the urn brighter.

After you finish sanding, you need to clean the dust on the surface of the wood.

Remarks:

Our in the wooden urn items in the sanding process, need to sanding process enough, several times sanding and polishing. You can rest assured that the sanding process of the urn, are more than 10 years with skilled staff, each step of the operation in place, depending on the wooden urn into a very good work. This process is also one of the important roles in the manufacture of high-end wooden urns.

Polishing

Our wooden ash boxes need to undergo multiple rounds of polishing during the production process. First, after the wood has been cut, it needs to be polished. This operation is mainly to remove any burrs and unevenness on the wood surface. The main workflow of our ash box polishing operation includes:

*Using sandpaper to polish the surface of the ash box to remove small burrs on the wood surface.

*Using a polishing machine to enhance the brightness of the ash box surface.

*After polishing, it's necessary to clean the dust off the wood surface.

Note:

When our wooden ash boxes enter the polishing stage, the process is repeated several times, with multiple rounds of polishing. Rest assured, the polishing process of the ash box is carried out by skilled workers with over 10 years of experience. Each step is executed meticulously, treating each wooden ash box as a masterpiece. This stage is also one of the key aspects that contribute to the high-end quality of our wooden ash boxes.

Paint spraying

There are a number of processes in our factory in the painting process. Craft spray paint operation, we strictly require are 3 times the base color paint, 2 times is the top coat. Not only that, our spray paint from the brand, not ordinary paint supply. So these are the hidden costs we processed into wooden urns. In addition, if the customer requires high end more high end black white etc, naturally the process increases quite a bit, then your cost of purchasing a wooden urn increases significantly. To summarize, our painting operation process is:

1- Before painting, the surface of the urn should be cleaned and degreased. ,

2- The painting process for urns includes:

-The painting process uses machine painting or manual painting to paint the surface of the urn.

-After painting, the surface of the urn should be dried and cured, so that the surface of the paint can be firmly combined with the surface of the wood in the process, and likewise, make the surface gloss of the paint more uniform.

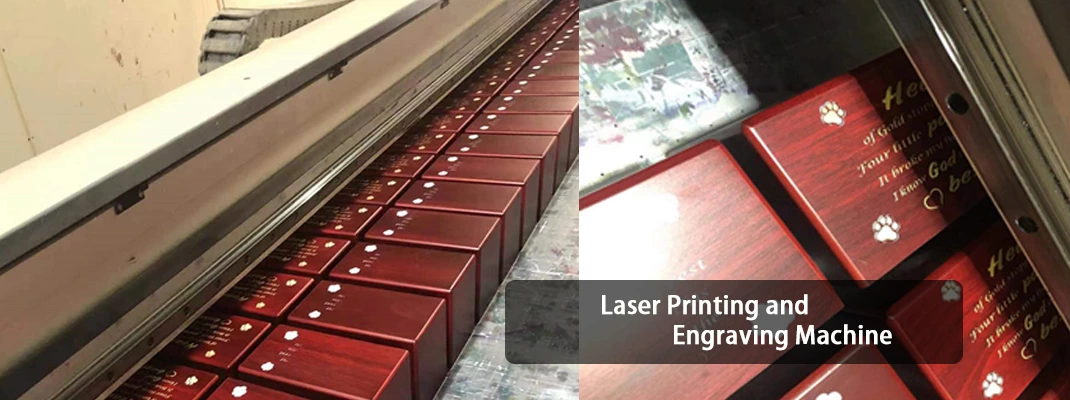

Laser Printing and Engraving Machine

Our workshop facilities are also equipped with automated custom processing equipment such as laser printers & engraving machines. So, if you have a special customized urn appearance pattern, with your retail brand logo engraved on the surface of the wooden box, size, capacity and other relevant parameters of the pet box specifications, we are available to serve you attentively. However, once you have a special pattern or text, we will follow a predetermined process, first through our factory technical team to confirm and determine whether it is OK, and then our foreign trade services team will respond to your needs. But don't worry, it won't take more than 1 day. We will try to get in touch with you by phone or e-mail within 24h.

Engraving machine, conversion of computer-recognizable file data and processing of wood according to a defined pattern.

Laser printing, input of computer-recognizable data, correction of the parameters of the printing device, and final printing of the pet urn.

Our engraving machines process wood to a controlled depth, allowing for shallow relief, deep relief and openwork engraving.

Our laser printers can print text, graphics and barcode information.

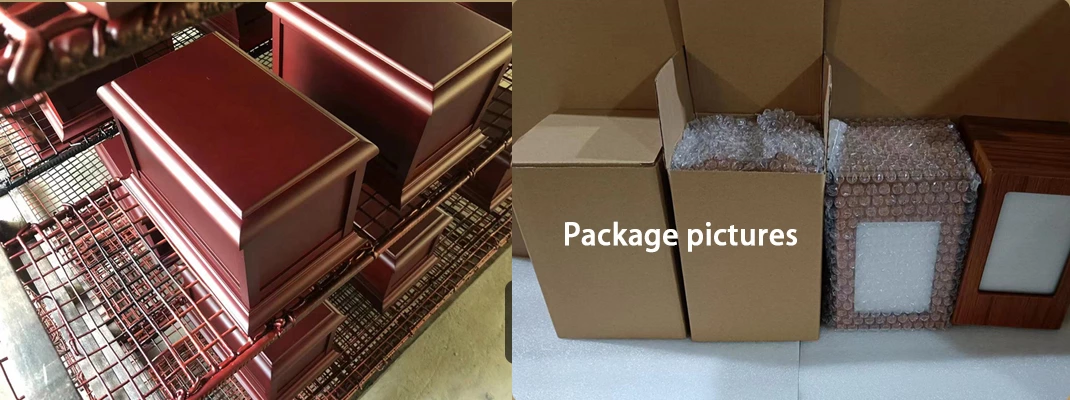

Packaging

After sourcing high-quality wood as raw material and going through several stages of processing, the final wooden cremation box enters the last step: packaging.

To better protect the wooden cremation boxes, we employ various packaging methods. Our factory selects an appropriate packaging box for the finished wooden cremation boxes. What materials do we choose for these boxes? Generally, we opt for cardboard, foam, and wooden crates.

Below are the steps we take to package our wooden cremation boxes:

1- For internal packaging, we use bubble wrap bags, and then embed cushioning foam on all six sides of the cardboard box.

2- The outer packaging is done using a cardboard box.

3- If the size and shape of the wooden cremation box is small or medium, we choose an additional larger cardboard box for packaging. If the pet cremation box is relatively large in size, we select an appropriate outer packaging to directly save unnecessary packaging costs.