Combining Tradition and Technology: Our Comprehensive Approach to Wood Product Production

In our Caoxian factory, we have prepared a complete industrial chain for wood product production facilities to ensure optimal efficiency and quality control at every step of the production process.

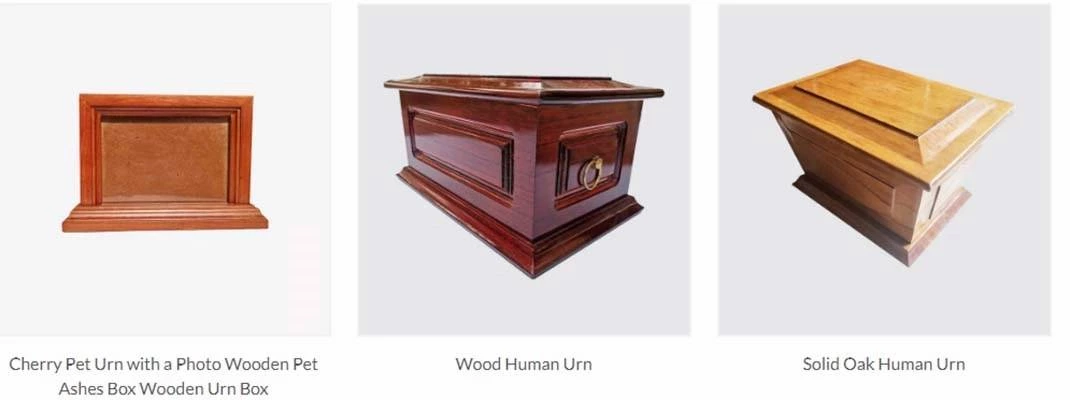

First, our assembly process is done by hand. Craftsmen carefully select the wood according to the design drawings and then assemble the individual components with precision. We use traditional woodworking techniques that have been developed and refined over centuries to ensure that the boxes are structurally sound and perfectly detailed.

Next, we sanded the box. This step requires great care and patience. Our craftsmen will use sandpaper to smooth the box bit by bit, ensuring it's nice to the touch and has no edges.

We will then paint the surface of the box. This step not only protects the wood from moisture and insects, but also adds to the aesthetics of the box. We will choose paints of different colors and gloss for construction according to customer needs.

Finally, we will package them in our own workshop. We will wrap the box with shock-proof packaging material to ensure it will not be damaged during transportation.

In addition, we handle other processes in-house based on the box design. For example, if a customer needs to engrave a pattern or text on a box, we will use a high-precision laser engraving machine to perform the operation. If the customer needs to print a logo on the box, we will use screen printing technology, which allows us to print clear and vivid images and is very durable.